Selling point

- Easy operation with the touch panel.

- You can use for multi-products, with the settings recording function.

- You can make fine adjustments to setting with the joystick.

- Easy to maintenance with a back door.

- We simplified the mechanism around film roll and succeeded in downsizing.

- You can produce the product with double pack, such as liquid and powder.

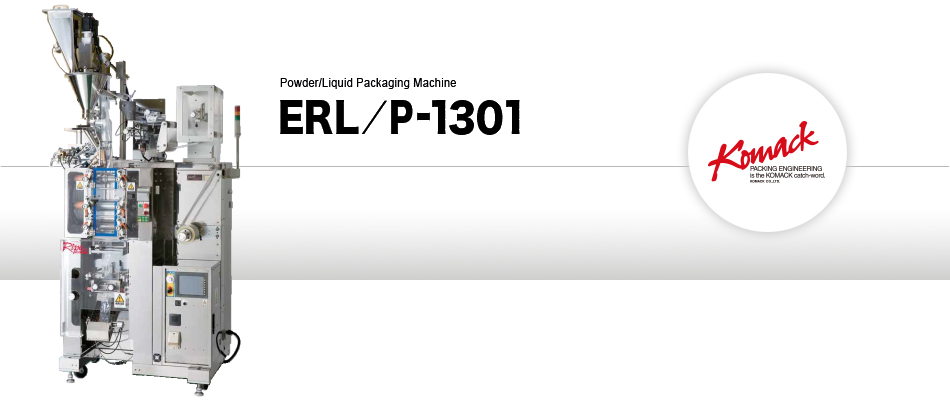

Standard Specifications

Filling material

Liquid and Powder

Pouch pattern

|

3-side seal or 4-side seal (Double pack) |

|

Packaging capacity

20-300/min.

Film loading speed

20m/min. (Max.)

Filling volume

1-200cc * Weighing range of filling volume depends on the filling material and feeder.

Pitch variable range

2 wings 125-230mm

3 wings 85-155mm

4 wings 65-115mm

6 wings 45- 80mm

Width variable range

25-130mm

Film width

50-260mm

Film Diameter

φ400mm (Max.)

Power source

3-phase 200V Approx. 7kW in total

Air consumption

Not in use (Some options use)

Machine Dimension

1,150mm (W) × 950mm (L) × 2,050mm (H)

Machine Weight

Approx. 700kg